Firstly What is Composite Material?

(copied from Wikipedia Composite material - Wikipedia)

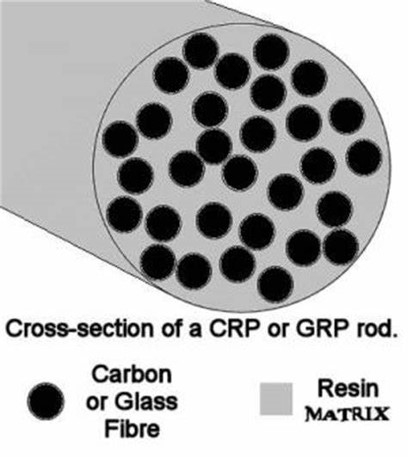

A composite material (also called a composition material or shortened to composite, which is the common name) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a material with properties unlike the individual elements. Within the finished structure, the individual elements remain separate and distinct, distinguishing composites from mixtures and solid solutions.

Typical engineered composite materials include:

- Reinforced concrete and masonry

- Composite wood such as plywood

- Reinforced plastics, such as fibre-reinforced polymer or fiberglass

- Ceramic matrix composites (composite ceramic and metal matrices)

- Metal matrix composites

- and other advanced composite materials

What is GRP/FRP?

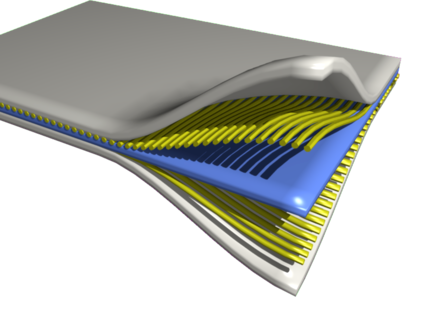

GRP material is a fiberglass reinforced plastic. The full form of GRP is glass-reinforced plastic. The fibers are usually glass, but can also be carbon or aramid. The plastic matrix is typically polyester, vinylester, or epoxy.

GRP refers to glass-reinforced plastic, a composite material made of fiberglass reinforcement and polyester or epoxy resin. The fiberglass is usually in the form of woven fabric or rovings, while the resin is either polyester or epoxy

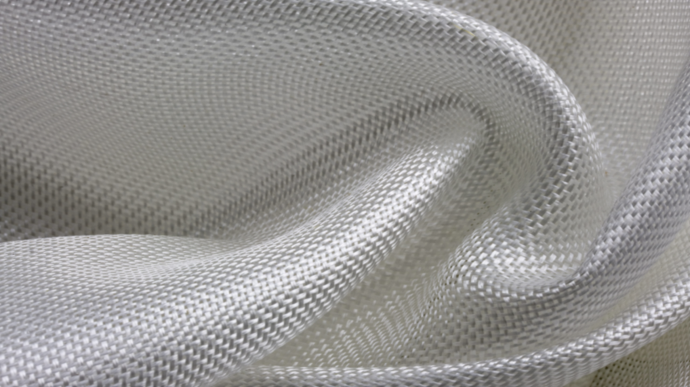

What is fiberglass?

Fiberglass was invented in the 1930s, initially developed for military uses in WWII and gaining more widespread use in the 1950s,

fiberglass composites have become a staple in the modern world.

The process of manufacturing fiberglass is called pultrusion.

The manufacturing process for glass fibers suitable for reinforcement uses large furnaces to gradually melt the silica sand, limestone, kaolin clay, fluorspar ,colemanite ,dolomite and other minerals until a liquid forms. It is then extruded through bushings (spinneret), which are bundles of very small orifices (typically 5–25 micrometers in diameter for E-Glass, 9 micrometers for S-Glass).

Using FRP products have many advantages such as:

Anti-Corrosion

Nile industries fiberglass reinforced plastic (FRP) products are known for their ability to provide corrosion resistance in the harshest environments and chemical exposures. Unlike metal and wood, FRP products will not rust or corrode and will continue to maintain structural integrity over time.

Low-Maintenance

The durability and corrosion resistance of Nile industries FRP molded and pultruded profiles and other products reduce or eliminate the need for heavy maintenance like sandblasting, scraping and painting. In fact, most Nile industries products are easily cleaned with a high-pressure washer.

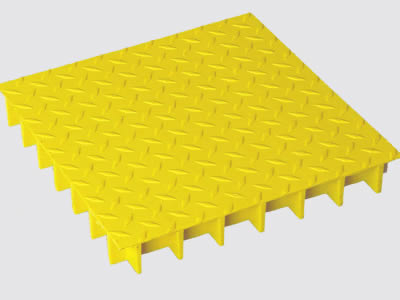

Slip Resistance

Nile industries' molded and pultruded gratings and stairway products provide superior, slip resistant footing in wet and oily environments. Steel becomes slippery when oily or wet, but Nile industries gratings have a higher friction factor and remain safe even when wet. Nile industries' slip resistant products increase safety for workers which will lead to fewer workplace accidents and a reduction of injury-associated costs

Low-Installation Cost

Steel installation can be time consuming and equipment intensive. Nile industries products can be easily and quickly cut with ordinary hand tools. Welding or hot work is not necessary with FRP. Nile industries fiberglass gratings are lightweight and can be installed easily with bolts and clips. Installation of FRP material can be done without using heavy equipment and machinery, requiring less manpower

Light Weight

The lightweight properties of Nile industries FRP result in products that weigh considerably less than steel. The density of steel is four times higher than that of FRP, and steel gratings are two to two-and-a-half times heavier than FRP gratings. FRP’s lighter weight allows easy removal for access below floor level. The reduction in weight that Nile industries products provide can save on material transit costs and installation costs.

Impact resistance

Nile industries FRP can withstand major impacts with negligible damage.

Nile

industries offers extremely durable gratings to satisfy even the most stringent

impact requirements.

Electric & Thermal Non-Conductive

Nile industries FRP is electrically non-conductive leading to increased safety compared to conductive materials (i.e., metal). FRP also has low thermal conductivity (heat transfer occurs at a lower rate), resulting in a more comfortable product surface when physical contact occurs

Uv resistance

Nile industries' fiberglass gratings and profiles are formulated for

maximum UV resistance

Our Products:

With over 20 years in business and highly trained specialist teams ,We are Still #1. Thanks for them.

Please get in touch and we’ll guide you through the process of choosing the right products to meet your objectives.